Choline chloride for livestock production: basic information and applications

Guidelines for Allicin in Cattle

January 24, 2025

Manufacturing Methods of Choline Chloride for Livestock: A Comprehensive Analysis

March 1, 2025Choline chloride for livestock production: basic information and applications

Choline Chloride is an important animal nutritional supplement and is widely used in feeds of poultry, livestock and aquatic animals. Here are the basic information and applications of choline chloride:

Basic information

-

Chemical Properties:

- Chemical formula: C5H14ClNO4

- Molecular weight: 139.63

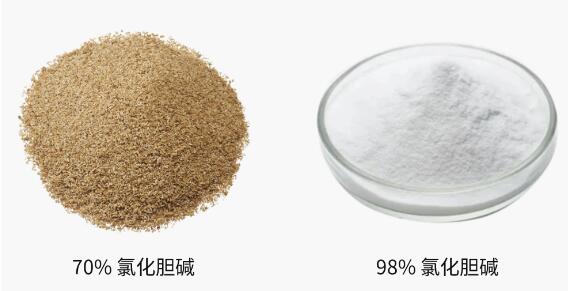

- Appearance: White crystalline powder or hygroscopic crystal

- Solubility: easy to soluble in water, insoluble in ethanol and benzene, unstable to alkaline solutions

-

Production method:

- It is mainly through chemical synthesis methods, such as ethylene oxide method and chloroethanol method. The ethylene oxide method is to react trimethylamine solution with ethylene oxide, and then produce crude product and decolorize activated carbon and concentrate in vacuo to obtain the product [4].

application

-

poultry:

- Promote growth: Improve the growth rate and feed conversion rate of poultry such as chickens, ducks, turkeys [1][2][5].

- Improve the quality of eggs and meat: Increase the yield and quality of eggs and improve the quality of meat [9][27].

- Prevent fatty liver: Prevent fat accumulation in the liver and kidneys and avoid pathological changes [1][5][6].

- Improve reproductive ability: stimulate egg laying in the ovaries and increase survival rate [1][5].

-

livestock:

- Promote growth: Improve the growth rate and feed conversion rate of livestock such as pigs and cattle [1][6].

- Improve meat quality: Improve meat quality and taste [1][6].

- Prevent fatty liver: Prevent liver fat accumulation and avoid pathological changes [1][6].

-

Aquatic animals:

- Promote growth: Improve the growth rate and survival rate of fish and shrimp [1][5].

- Improve reproductive ability: stimulate reproduction and increase the number of larvae [1][5].

How to use

- Added amount: The added amount varies depending on the animal species and growth stage. For example, poultry adds 250-600 grams per ton of feed at 0-8 weeks of age, and adult chickens adds 500-700 grams per ton of feed [2].

- Carrier: Usually mixed with corn flour, bran and other carriers and added to the feed [7].

- Storage conditions: It should be stored in a cool and dry place to avoid high temperature and humidity [1].

Safety and quality standards

- Safety: Choline chloride is widely considered safe (GRAS), but contact with the skin and eyes should be avoided and thoroughly washed after treatment [22].

- Quality standard: Comply with GB34467-2017 standards, high purity requirements, usually not less than 99%[1][18].

in conclusion

Choline chloride, as an important animal nutritional supplement, can not only promote the growth and development of animals, but also improve their health and reproductive ability. In practical applications, the rational addition of choline chloride can significantly improve the breeding benefits and is an indispensable nutritional additive in modern animal husbandry.

Current manufacturing methods of choline chloride for livestock

Currently, the manufacturing methods of Choline Chloride in livestock and poultry feed mainly include the following:

-

Traditional synthesis method: This is the most commonly used method, which reacts trimethylamine hydrochloride and ethylene oxide to form choline chloride through chemical reactions. The specific steps include pumping the trimethylamine hydrochloride solution and ethylene oxide into the reactor respectively, with the reaction time of 1-1.5 hours and controlling the reaction temperature within a certain range to ensure the smooth progress of the reaction [31].

-

Biofermentation method: This method uses microbial fermentation technology to produce choline chloride, which is environmentally friendly and sustainable. Although it is currently used on industrial scale, its potential is huge [56].

-

Green production process: In recent years, with the improvement of environmental protection requirements, green production process has gradually attracted attention. This approach usually uses more environmentally friendly raw materials and processes to reduce energy consumption and waste emissions [56].

-

Industrial synthesis method: Commonly used synthesis methods in the industry include the use of hydrochloric acid, trimethylamine and ethylene oxide as raw materials to produce choline chloride through chemical reactions. This method is simple and efficient, but requires strict control of reaction conditions to ensure product quality [1].

-

Laboratory synthesis method: In the laboratory, choline chloride can be synthesized by a variety of methods, such as using choline chloride and oxalic acid (Oxalic Acid) to produce under certain conditions [50].

These methods have their own advantages and disadvantages. Traditional synthesis methods are widely used in industrial production because of their high efficiency and low cost, while biofermentation methods and green production processes are gradually being valued for their environmental protection and sustainability.

② detailed chemical synthesis process parameters

The traditional synthesis method of choline chloride is mainly prepared by the reaction of ethylene oxide (EO) and trimethylamine hydrochloride (TM AHCl). The following are detailed chemical synthesis process parameters:

-

Raw material ratio:

- The molar ratio of ethylene oxide (EO) and trimethylamine hydrochloride (TM AHCl) is 1.05~1.10:1.00. [57]

-

Reaction temperature:

- The reaction temperature is controlled between 60 and 70℃. [57]

-

Reactor type and operating conditions:

- Use a bubble reactor or a static mixing reactor.

- The reactor stages are 2 to 3 levels, and the residence time is 10 to 15 minutes. [57]

- The residence time of the reactants in the reactor is 1 to 1.5 hours. [58][62][63]

-

Adding method:

- Use one-time feeding method. [57]

-

Reaction process:

- First, trimethylamine is reacted with hydrochloric acid to form trimethylamine hydrochloride.

- The trimethylamine hydrochloride is then reacted with ethylene oxide to produce choline chloride. [58][63]

-

Post-processing:

- After the reaction is completed, the choline chloride product is separated and purified by decompression distillation and rotary evaporator. [58]

-

Yield and purity:

- Under the optimized conditions, the average yield of choline chloride was 95.8% and the purity was 99.8%. [58]

These parameters ensure the efficient synthesis and high purity of choline chloride, and are suitable for industrial production.

② raw material requirements and purity standards

In the production of Choline Chloride, the raw material requirements and purity standards required for traditional synthesis methods, biofermentation methods and green production processes are as follows:

Traditional synthesis method

-

Raw materials:

- Trimethylamine (TMA): Usually uses industrial or food grade trimethylamine, with high purity requirements to ensure the quality of the final product.

- Hydrochloric Acid (HCl): Generally, industrial-grade hydrochloric acid is used, with high purity requirements.

- Ethylene Oxide (EO): used to react with trimethylamine to form choline chloride.

-

Purity standard:

- Trimethylamine: The purity requirement is above 99%, and the specific value may vary from manufacturer to manufacturer.

- Hydrochloric acid: The purity is required to be above 99%, usually at analytical pure or laboratory reagent grade.

- Ethylene oxide: The purity is required to be above 99%, usually at the industrial grade.

Biofermentation

-

Raw materials:

- Microorganisms: such as E. coli or Corynebacterium glutamicum, etc., used to ferment and produce choline.

- Culture medium: including glucose, yeast powder, corn dry powder, etc., used for the growth and metabolism of microorganisms.

-

Purity standard:

- Microorganisms: They need to undergo strict screening and culture to ensure their activity and safety.

- Culture medium: It must meet food-grade standards and has high purity requirements.

Green production process

-

Raw materials:

- Natural sources: such as yolk, vegetable oil, etc., choline is obtained through extraction and hydrolysis.

- Solvents and Catalysts: Use environmentally friendly solvents and catalysts to reduce by-products and environmental pollution.

-

Purity standard:

- Natural source: Strict quality control is required to ensure that it is free of heavy metals and other harmful substances.

- Solvents and catalysts: They must meet environmental protection standards and have high purity requirements.

Summarize

- Traditional synthesis method: mainly relies on chemical raw materials, such as trimethylamine, hydrochloric acid and ethylene oxide, with high purity requirements.

- Biofermentation method: Relying on microbial fermentation, it is necessary to ensure the activity of the microorganisms and the purity of the culture medium.

- Green production process: Focus on environmental protection, use natural sources and environmentally friendly solvents, and strictly purity requirements.

These methods require strict control of the purity and quality of the raw materials during the production process to ensure the safety and effectiveness of the final product. [3][88][58]

② quality control indicators for livestock-grade choline chloride

The quality control indicators of livestock and poultry grade choline chloride mainly include the following aspects:

-

Appearance:

- Solid state: consistent color, no fermentation, mold, clumping, odor or odor.

- Liquid: a colorless liquid, uniform color and odor-free solution. [106]

-

Moisture:

- The moisture content is not higher than 12.0%. [106]

-

pH:

- The pH value is 3.0~13.0. [106]

-

Processing quality index:

- Crushing particle size: 95% of the total amount passes through a standard woven screen with a pore size of 0.45mm to 0.15mm.

- Mixing uniformity: Mix evenly, and its coefficient of variation (CV) is not greater than 5%. [106]

-

Health indicators:

- Sanitary indicators should comply with the requirements of relevant standards. [106]

-

Choline chloride content:

- The content of choline chloride is based on dry basis, and the specific values vary according to the implementation standards. For example, GB 34462-2017 stipulates that the choline chloride content of water agents and powders is 70%, 75%, 80%, 50%, 60%, and 70%, respectively. [116]

-

Other physical and chemical indicators:

- Ethylene glycol content: ≤0.20%.

- Incineration residue: ≤0.05%.

- Total free amine/ammonia (in (CH3) 3N): ≤0.03%.

- Heavy metal (in Pb): ≤0.002%.

- Trimethylamine residue: ≤300ppm.

- Nitroimidazoles (calculated in DDT): ≤0.02mg/kg.

- Aflatoxin B2: ≤20ppm.

- Dioxin VII: ≤0.0075ppm.

- Blue light scattering value: ≤1.0. [113][77]

-

Inspection method:

- Methods for determining the content of choline chloride include Kjeldahl method, Karl Fischer method, etc.

- The method for determining pH and glycol content is shown in GB/T 9724.

- For the determination method of total free amine/ammonia, see GB/T 14691. [107][111]

-

Packaging, transport and storage:

- The packaging should comply with the provisions of GB 10616 and be packaged in a non-toxic composite film bag that meets hygiene requirements.

- During transportation, the car box should be protected from rain and the car box should be sanitary. It should be avoided during transportation and stored in a ventilated, cool and dry environment to avoid mixing with toxic and harmful items. [106][113]

These indicators ensure the quality and safety of livestock and poultry grade choline chloride and are suitable for the production of livestock and poultry feed additives.

② safety precautions and environmental regulations

Choline Chloride’s safety precautions and environmental regulations in livestock and poultry feed production mainly include the following aspects:

Safety precautions

-

Storage conditions:

- Choline chloride should be stored in a cool, dry, well-ventilated place away from fire and heat sources. Avoid direct sunlight and prevent moisture absorption and decomposition [29].

- The storage temperature should be kept between 0-6°C and avoid heating to decomposition [136][60].

-

How to use:

- Use according to product instructions and recommended by professionals to avoid excessive use [134][137].

- When mixing with other feed additives, the correct order of addition should be followed to prevent damage to other vitamins [143].

- Regularly monitor the health status of livestock and poultry to ensure the effectiveness of choline chloride [137].

-

Personal Protection:

- Goggles and gloves should be worn when treating choline chloride to avoid inhaling dust, steam or mist [29][151].

- If you accidentally touch the skin or eyes, you should immediately rinse with a lot of clean water and seek medical help [136].

-

Emergency handling:

- In case of a leak, the affected person should be removed quickly, away from the dangerous area, and appropriate first aid measures should be taken [136].

- When taking the drug center incorrectly, you should call the poison center immediately and keep the respiratory tract unobstructed [136].

Environmental regulations

-

-

National Standards:

- The national standard “Feed Additives Part 2: Vitamins and Retinoid Choline Chloride” stipulates the production requirements, testing methods, inspection rules, and specifications for choline chloride, such as labeling, packaging, transportation, storage and shelf life [135][111 ][144].

- The raw materials for feed-grade choline chloride include choline chloride produced by reacting aqueous trimethylamine hydrochloride solution with ethylene oxide [144].

-

International regulations:

- The European Food Safety Agency (EFSA) confirms the safety and efficacy of choline chloride as an animal feed additive, suitable for all animal species without the need to set a maximum limit [140].

- Federal regulations require that choline chloride be followed as a food nutritional component or animal medicine, feed and dietary supplement [139].

-

Shipping and packaging:

- Choline chloride should prevent packaging from being damaged during transportation, and it is prohibited to mix it with toxic and harmful substances. The powder should also have a light shield to prevent sun and rain [96].

- Packaging materials should be non-toxic, harmless, moisture-proof, and prevent sunlight and rain [111].

-

Environmental protection measures:

- When using choline chloride, environmental protection measures should be paid to avoid pollution to the environment [142].

- Waste should be properly disposed of in accordance with local environmental regulations [134].

-