Choline Chloride Supplementation in Poultry

Can Betaine or Methionine Replace Choline Chloride for Poultry?

January 12, 2025

Allicin Benefits, Side Effects, Supplements, and Dosage for Cattle

January 20, 2025Practical Approach to Choline Chloride Supplementation in Poultry

Choline chloride supplementation plays a vital role in poultry nutrition, ensuring optimal growth, performance, and health. The practical approach to supplementing choline chloride involves understanding its role, determining the correct dosage, and integrating it efficiently into feed formulations based on poultry species, growth phases, and environmental factors.

1. Understand the Purpose of Choline Chloride Supplementation

Choline chloride is a key nutrient that performs multiple essential functions in poultry:

- Lipid Metabolism: Prevents fat accumulation in the liver by aiding lipid transport.

- Phospholipid Formation: Necessary for cell membrane integrity and function.

- Nervous System Development: Supports acetylcholine synthesis, a neurotransmitter for proper nerve function.

- Methyl Group Donor: Contributes to metabolic reactions requiring methylation, such as DNA synthesis.

Without adequate choline, poultry may experience fatty liver syndrome, growth retardation, poor egg production, and overall reduced performance.

2. Calculate Choline Requirements

The choline chloride requirement for poultry varies depending on factors such as species, age, growth phase, production goals, and dietary composition. Here’s a general guideline:

| Poultry Type | Choline Requirement (mg/kg of feed) |

|---|---|

| Broiler starter | 1300–1500 |

| Broiler grower | 1000–1200 |

| Broiler finisher | 700–900 |

| Laying hens | 400–600 |

| Breeders (layers) | 1200–1500 |

| Ducks and turkeys | 1300–1600 |

Key Considerations:

- Growth Phase: Young birds require higher choline levels due to rapid growth and development.

- Production Goals: Layers and breeders require choline for egg quality and hatchability.

- Diet Composition: Feed rich in methyl donors like methionine or betaine may reduce the need for choline chloride supplementation.

Choline Chloride Parameter Table

Below is a detailed table summarizing the essential parameters of choline chloride, including its chemical properties, forms, recommended inclusion rates, and storage guidelines:

| Parameter | Details |

|---|---|

| Chemical Name | Choline chloride |

| Chemical Formula | C5H14ClNO |

| Molecular Weight | 139.63 g/mol |

| Physical Appearance | White crystalline powder (powder form) or colorless liquid (liquid form) |

| Concentration | – 50% for powder (mixed with carriers like corn cob or silica) |

| – 70% for liquid | |

| Solubility | Highly soluble in water and ethanol |

| Stability | Stable under normal storage conditions; heat-sensitive |

| pH (10% aqueous solution) | 5.5–8.5 |

Nutritional and Functional Parameters

| Nutritional Role | Details |

|---|---|

| Primary Function | Methyl donor, phospholipid synthesis, and lipid metabolism |

| Additional Benefits | Supports nerve function, egg production, and prevents fatty liver |

| Species-Specific Requirements | Varies by poultry type and growth stage (see next table for dosage). |

Choline Chloride Inclusion Rates for Poultry

| Poultry Type | Growth Phase | Recommended Dosage (mg/kg of feed) |

|---|---|---|

| Broilers | Starter (0–3 weeks) | 1300–1500 |

| Grower (4–6 weeks) | 1000–1200 | |

| Finisher (7 weeks +) | 700–900 | |

| Layers | Pullet (0–18 weeks) | 900–1200 |

| Laying phase | 400–600 | |

| Breeder Hens | Breeding period | 1200–1500 |

| Turkeys and Ducks | All phases | 1300–1600 |

Comparison Between Powder and Liquid Forms

| Parameter | Powder Form (50%) | Liquid Form (70%) |

|---|---|---|

| Concentration | 50% active ingredient | 70% active ingredient |

| Appearance | Dry, white crystalline powder | Clear, colorless liquid |

| Solubility | Easily mixed with dry feed | Easily soluble in water or liquid feed |

| Feed Inclusion Method | Direct mixing into feed | Dilution into drinking water or liquid feed |

| Shelf Life | 1–2 years (stored in a dry, cool environment) | 1 year (stored in a sealed container at room temp) |

Storage and Handling Parameters

| Parameter | Details |

|---|---|

| Storage Conditions | – Store in a cool, dry place away from sunlight. |

| – Avoid exposure to high humidity to prevent clumping in powder form. | |

| Shelf Life | – Powder form: 12–24 months under proper conditions. |

| – Liquid form: Up to 12 months when stored in sealed containers. | |

| Compatibility | Compatible with most feed ingredients; avoid mixing with alkaline substances. |

| Packaging | – Powder: Packed in 25 kg or 50 kg bags with polyethylene lining. |

| – Liquid: Supplied in sealed drums or containers. | |

| Handling Precautions | – Use protective gloves and masks to avoid inhalation or skin irritation. |

Feed Safety and Toxicity

| Parameter | Details |

|---|---|

| Toxicity | Low toxicity when included at recommended levels. |

| Overdose Effects | Excessive inclusion can lead to feed cost inefficiencies, diarrhea, or nutrient imbalances. |

| Maximum Safe Level | 2000–3000 mg/kg of feed (depending on species and diet composition). |

3. Formulate the Feed Appropriately

To include choline chloride in poultry diets effectively, follow these practical steps:

Choose the Right Form of Choline Chloride

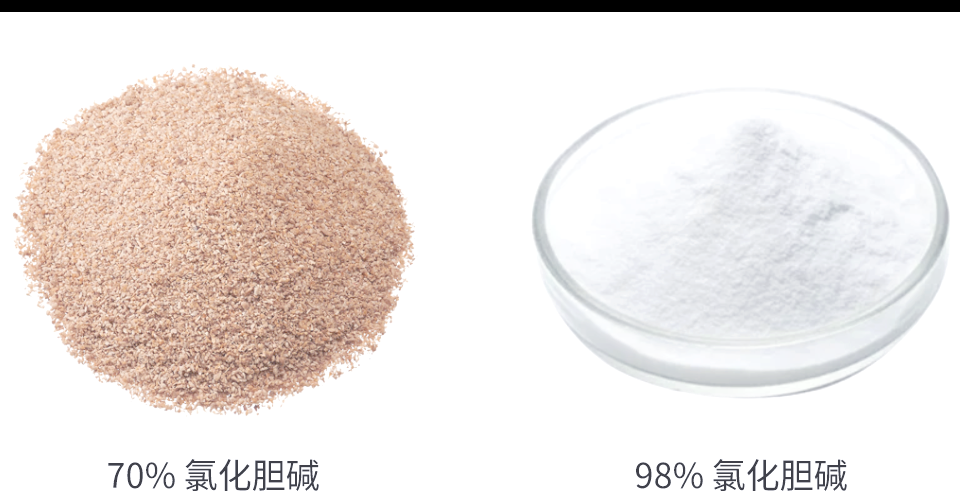

Choline chloride is typically available in two forms:

- Powder (50% concentration): Suitable for dry feed formulations.

- Liquid (70% concentration): Ideal for mixing with liquid feed or water.

Incorporate into Feed Formulation

Choline chloride is added as part of a balanced feed formulation. Key steps include:

- Feed Mixing: Use precision weighing systems to add the correct amount of choline chloride to the feed to avoid under- or over-supplementation.

- Premixes: Combine choline chloride with other vitamins and minerals to ensure even distribution in the final feed.

- Heat Stability: If choline chloride is included in pelleted feeds, ensure that it can withstand the heat of the pelleting process to avoid degradation.

4. Balance Choline with Other Nutrients

For cost-efficiency and optimal nutrient absorption, balance choline chloride with other nutrients, such as:

Methionine

- Methionine is an essential amino acid that can spare some of choline’s methyl donor functions.

- Formulating diets with adequate methionine (0.3–0.5% of feed) can reduce the required choline chloride levels.

Betaine

- Betaine acts as a methyl donor and an osmolyte, especially under stress conditions.

- Including betaine (500–2000 mg/kg of feed) can reduce the amount of choline chloride required in feed formulations.

Vitamin B12

- Vitamin B12 works synergistically with choline and methionine in methylation processes.

- Adequate vitamin B12 levels improve choline utilization and overall performance.

5. Monitor Environmental and Management Factors

Environmental conditions and management practices affect the efficacy of choline chloride supplementation. Practical adjustments include:

Heat Stress

- During high-temperature conditions, consider supplementing with both choline chloride and betaine to improve performance and reduce stress.

Water Quality

- Liquid choline chloride added to water should only be used if the water source is clean and free of contaminants, as poor water quality may reduce nutrient absorption.

Feed Quality

- Ensure the feed has adequate levels of fat, protein, and other essential nutrients to support choline chloride’s function in lipid metabolism and growth.

6. Prevent Over- or Under-Supplementation

Both excessive and insufficient choline chloride supplementation can negatively impact poultry performance:

Over-Supplementation Risks

- High levels of choline chloride are usually safe, but excessive inclusion can lead to cost inefficiency and potential antagonistic effects on other nutrients.

Under-Supplementation Risks

- Deficiency in choline chloride can result in:

- Fatty liver syndrome.

- Poor feed conversion rates.

- Stunted growth and skeletal deformities.

- Reduced egg production and poor egg quality.

Practical Tip:

Use regular feed analysis and performance monitoring to adjust choline chloride supplementation based on actual requirements and environmental conditions.

7. Cost-Effective Supplementation

To reduce costs without compromising performance, consider:

- Partial Substitution with Betaine or Methionine: Use betaine and methionine to reduce the amount of choline chloride required for methylation functions.

- Evaluate Feed Composition: Include natural feed ingredients like soybean meal and corn gluten, which contain small amounts of choline.

8. Monitor Performance Indicators

Assess poultry health and productivity regularly to determine if choline chloride supplementation is meeting their needs. Key performance indicators include:

- Growth rate and body weight gain.

- Feed conversion ratio (FCR).

- Egg production, hatchability, and egg quality in layers.

- Liver health (monitor for signs of fatty liver syndrome).

- Mortality and overall flock health.

9. Consult Nutritionists and Veterinarians

Work closely with poultry nutritionists and veterinarians to optimize feed formulations and ensure proper supplementation. Their expertise can help fine-tune choline chloride levels based on the specific needs of your flock and production goals.

Conclusion

A practical approach to choline chloride supplementation involves understanding the nutrient’s critical role, calculating species-specific requirements, balancing it with other nutrients, and monitoring flock performance. While choline chloride remains the primary source of choline in poultry diets, incorporating methionine and betaine strategically can improve cost-efficiency and nutrient utilization.

Regular feed analysis, environmental monitoring, and expert consultation are essential to ensure optimal supplementation, prevent deficiencies, and achieve the best results for growth, egg production, and overall health in poultry.