Quality control of feed ingredients

Application of corn gluten meal in feed industry

June 11, 2019

Does Corn Gluten work effectively to control weed?

June 18, 2019 With the rapid development of the feed industry and the frequent fluctuations in raw material prices, the feed ingredients selected by feed enterprises are increasingly diversified and complicated. Controlling the quality of feed ingredients is of great practical significance for ensuring the quality of compound feed products. . The quality control of feed ingredients mainly includes on-site quality control and laboratory analysis of raw materials and quality inspection during raw material inventory. This paper mainly analyzes the quality control of feed enterprises from raw material to processing before processing. According to the production process, the quality control of raw materials, the testing of raw materials, the storage of raw materials and the quality monitoring of raw material storage process, etc. In one aspect, we will discuss how to make a good view of the quality of raw materials and the storage of raw materials, and briefly describe the methods for quality control of feed ingredients.

1 On-site quality control of feed ingredients

On-site quality control of feed ingredients is the first step in quality testing of raw materials entering feed enterprises. It is easy to operate and quick to respond, but it also requires on-site quality control personnel to have good professionalism and responsibility. It is possible to increase the probability of successfully identifying the quality of the raw materials.

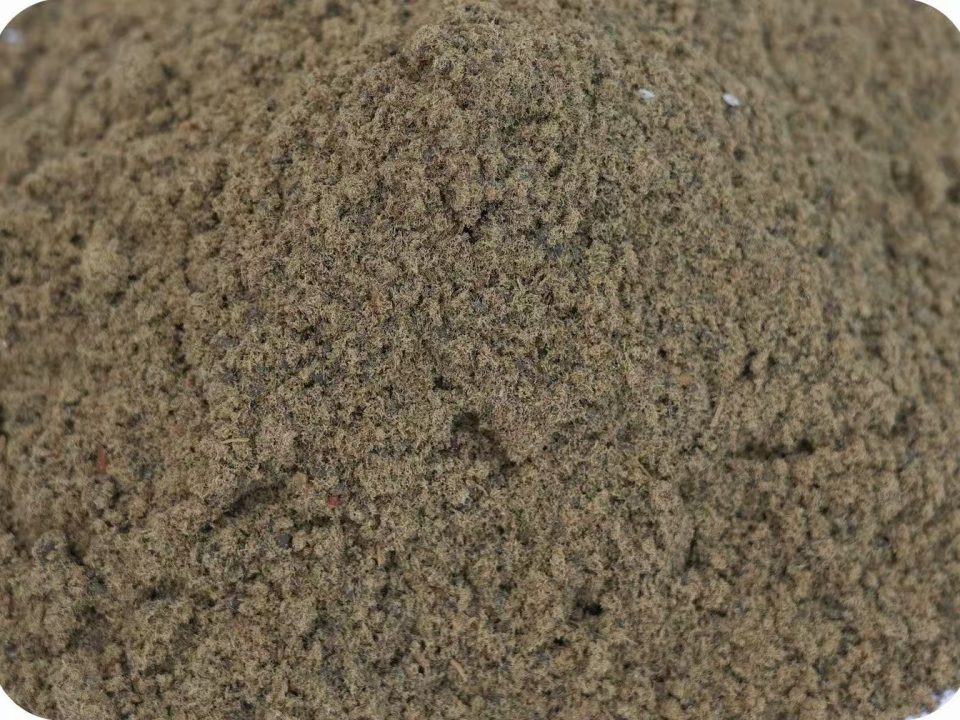

On-site quality control usually uses sensory organs such as “eyes”, “hands”, “nose” and “mouth” to identify the quality of feed ingredients. “Eyes” refers to observing the color, shape, and foreign matter of impurities in the raw material through the eyes. For example , the color of soybean meal prepared by different soybeans is different. The color of soybean meal prepared by Brazilian soybean is reddish, the color of soybean meal in the United States is white, and the black bean of Argentina has obvious black spots, and the protein and amino acid composition of the three are quite different; If there is rice husk mixed in the bran, the slender rice husk can be found after careful identification; if the corn quality is determined by observing the fullness of the corn , imperfect granules and mildew granules, and the amount of coke grains. Identify. The “hand” is the quality of the raw material by the touch of a finger and finger grinding. For example, by gripping and loosening the hand to sense the adhesion of the raw material and the hand to distinguish whether the moisture content of the rice bran is abnormal, usually the high-moisture rice bran will adhere to the skin, showing that the pile is not easy to spread; or as in the palm of the hand by finger grinding Bran, such as foreign matter mixed with rice husks, produces a stinging sensation. “Nose” refers to the change in the quality of raw materials through the sense of smell. Raw materials with strong taste often show large differences in odor due to changes in quality. For example, normal fresh fishmeal has a fishy aroma and inferior fishmeal has a pungent astringent, aroma or burnt taste; and, as the oxidatively deteriorated rice bran often exhibits a rancid taste. “Mouth” means the quality of the raw material is determined by taste of the raw material. For example, the quality of corn is identified by the method of tooth shredding. When the moisture of the corn is low, the teeth have a feeling of shaking teeth and have a crisp sound. When the water is too high, there is no feeling of shaking the teeth, and the corn is easily broken. Another example is the mouth taste fat , bad fat with sour, bitter, spicy taste bitter or coke, and quality of fat is no smell.

2 Laboratory testing of raw materials

For modern large-scale feed enterprises, there are many types of feed ingredients and the sources are complex. Therefore, it is necessary to quantify the quality of raw materials through laboratory physical and chemical indicators. If large-scale laboratory testing of raw materials is necessary, it will not be a small expense. Therefore, laboratory testing of raw materials should be based on on-site quality control to select some items that must be tested for analysis. Routine physical and chemical indicators for laboratory testing of raw materials include moisture, protein, crude fat, ash, calcium and phosphorus, while for some special raw materials, non-conventional indicators such as amino acids, small peptides, fatty acids and aflatoxins are sometimes detected. The moisture content of the feed ingredients affects the level and storage of effective nutrients, while the detection of moisture in actual production is also simple and easy, so moisture is one of the frequent testing items for feed ingredients. Due to regional and seasonal differences, feed companies often make different standard requirements for the moisture content of raw materials according to the seasons. Generally, the standard moisture content requirements for raw materials in summer are 0.5 to 1% lower than the winter requirements. The nutritional value of feed ingredients is determined by the efficacy and content of its nutrients. Setting a reasonable laboratory physical and chemical indicators test project has important practical significance for evaluating the price of feed ingredients and purchasing raw materials with good quality and good quality. In actual production, feed companies often set some mandatory laboratory testing items according to the type and use of raw materials as the standard for purchasing raw materials. For protein feed ingredients, commonly tested items include protein and non-protein nitrogen, and if necessary, the composition and content of amino acids and protein digestibility. For grain-based energy feed ingredients, items often tested include total energy and crude fiber, and soluble starch content can be detected if necessary. For oily feed ingredients, items often tested include acid value, iodine value, saponification price, etc., and if necessary, the composition and content of fatty acids. For mineral feed ingredients, items often tested include ash and mineral element content, and heavy metal elements can be detected if necessary.

Due to the development of detection and analysis technology and the urgent need of feed enterprises for raw material testing results, some rapid and high-throughput detection methods are gradually applied to laboratory testing and analysis of feed ingredients. In recent years, NIR technology has been gradually accepted and adopted by feed enterprises, which can quickly and accurately determine the relevant parameter indicators of the nutritional value of feed ingredients. According to reports in the literature, the use of near-infrared spectroscopy to establish animal protein feed (including meat and bone meal, fishmeal and poultry by-products), cereals (including wheat, corn, barley), a general calibration model and special calibration models for meat and bone meal, fishmeal and soybean meal The correlation coefficients are all above 0.90, which indicates that the detection results using near-infrared technology have good reliability. In addition to the near-infrared technology, the use of near-infrared technology is expensive. Due to the variety of feed ingredients and the complexity of the source, feed companies need to establish models suitable for their common raw materials according to the model, but establish a model with high reliability. It takes a lot of data, which is a long-term and difficult thing.

Conventional physical and chemical indicators quantify the quality of feed ingredients to a certain extent. However, the final effect of feed ingredients is to provide effective nutrients for animals. Therefore, the effective utilization index of raw material nutrients can further deepen the detection method system of raw material quality. The traditional detection method is to test the effective utilization efficiency of feed ingredients according to animal experiments, but such methods are time-consuming and labor-intensive, and the detection cost is high. In recent years, with the improvement of people’s understanding of the digestive physiology of animals, the in vitro simulation method to detect the dialysis rate of raw materials is highly correlated with the digestibility of animal experiments. The detection results are gradually recognized and accepted. Digestibility fish meal is fish meal can be a true reflection of digestion and absorption of protein content, it is an important indicator of quality evaluation of fish meal, fish meal FAO to develop food standards set forth in its stomach protease digestibility should be greater than 92.0%, the Peruvian fishmeal specified in the standard The pepsin digestibility of high quality fishmeal should be 94.0~95.0%, and the Chilean fishmeal quality standard is 94.0%. Since many raw materials have no uniform in vitro digestibility standards, it is necessary for enterprises to establish a stable set of in vitro experimental methods and related indicators according to the actual conditions of the raw materials they purchase as a standard for evaluating the quality of raw materials. When using the in vitro method to detect the quality of raw materials, some test indicators should be set according to different types of raw materials to optimize the detection procedure. The protein in vitro digestibility can be set for protein raw materials, and the in vitro digestibility of amino acids can be detected if necessary. The raw material can set the energy in vitro digestibility (digestible energy) and, if necessary, the monosaccharide dialysis rate. The reaction conditions in the in vitro experiment are easy to control, and the detection results have good repeatability. The determination of the in vitro digestibility of the raw materials can provide a reference for further evaluation of the quality of the raw materials.

3 storage of raw materials

Due to the frequent changes in the price of feed ingredients and the large price gap, large feed enterprises usually purchase large quantities of raw materials in warehouses at low prices to improve their competitiveness. The following several problems are often encountered when setting the storage space of raw materials. First, the special nature of the original cooking. Different feed materials have different requirements on the storage and storage environment. For example, rice bran, fish meal, oil cake and full-fat soybeans are prone to fat oxidative deterioration during storage, which causes the feed value to decrease. It needs to be stored in a well-ventilated temperature. In a suitable environment. Second, the volatility of raw material selection. For feed processing enterprises, when the price of raw materials changes drastically, it usually changes the type and quantity of raw materials used in the adjustment of feed formula . Sometimes, a large number of new raw materials with suitable prices need to be put into storage, which is a small enterprise with a small storage space. In terms of how to make room for reasonable storage of raw materials, it is difficult. Third, the complexity of the source of raw materials. With the development of the feed industry, the sources of feed ingredients are increasingly rich. For example, soybean meal prepared by different varieties of soybeans in different producing areas has large differences in protein content and amino acid composition. At the same time, in order to improve the bargaining power of raw material procurement, feed enterprises usually choose multiple sources of supply for the same raw material, and different manufacturers usually have large differences in the nutritional value and sanitary quality of raw materials or production processes. Fourth, the variety of raw material types. In order to balance the nutritional needs and optimize the cost of feed formulation as much as possible, the feed ingredients selected by modern feed enterprises are increasingly complicated and diversified. Generally, a company that produces full-price compound feeds often stores twenty or thirty kinds of raw materials. Many companies that need to produce a variety of feeds require more types of feed ingredients.

Due to the prevalence of the above problems, in some feed enterprises, raw material storage often appears to be somewhat confusing and blind, which is indeed a weakness for a company that pursues high quality and standardized management. Paying attention to raw material storage, it is necessary to reasonably set the storage space of raw materials according to the physical and chemical properties of the raw materials themselves and the market changes in procurement. The following items can be referred to for the setting of the raw material storage space. First, the storage space of the material with special requirements is preferentially set according to the physical and chemical properties of the raw materials. For example, feed enzyme preparations that are easily deactivated should be placed in a low-temperature and ventilated environment, and materials that are easy to absorb moisture and moisture should be placed in a dry and ventilated environment. Second, the raw material storage space is set according to the type and quantity of the feed ingredients. The same type of raw materials can be placed in the same area. For livestock and poultry compound feed, the amount of energy and protein feed ingredients is larger, while the mineral feed ingredients are less, and a large amount of raw materials should be set for the same type of raw materials. Storage space, while using less frequent and less used raw materials can leave less storage space. For example, for protein feed ingredients, the larger amount of soybean meal can set a larger storage space, while the lesser amount of protein materials such as fish meal, rapeseed meal and cottonseed meal can leave a small storage space. The rapid fluctuation of the current feed raw material market and the rapid development of compound feed technology have made the structure of feed formula materials vary greatly. However, the use of the same type of feed ingredients is relatively stable, which makes it feasible to preset the storage space according to the type of feed ingredients. . Third, the same raw materials are stored in grades by source. Due to differences in origin and production processes, there may be large differences between the same raw materials purchased in different batches, such as DDGS.The fat content distribution is 6-12%, and the energy difference of DDGS differing by 1% fat content is relatively large. Therefore, the graded storage according to the raw materials helps to accurately select suitable raw materials to prepare the compound feed. Fourth, follow the principle of innovation. When the raw material is put into storage, it can be stored from left to right, and the raw materials are taken from the same way, and when the intermediate position is set, the orientation order of the storage space is changed, so that the raw materials are stored from the storage to the use time. The shortest interval ensures the freshness of the raw materials. In this process, the role of the signage is very important, not only to identify the name, source, quality and warehousing time of the raw materials, but also to clearly identify the same raw materials at different warehousing times. Fifth, set up fixed and maneuverable storage space. For companies with small storage spaces, the role of setting up some fixed and maneuverable storage spaces is even more pronounced. For example, companies need to use multiple grades of fishmeal, and the storage time is usually 2-3 months. If a fixed storage area is set for it, it may be more helpful to monitor the quality change and correct and fast. Choose the appropriate level of fishmeal for production. In addition, enterprises often purchase a large number of high-quality and low-cost raw materials at appropriate time. When planning the storage area, set a maneuvering area outside the storage area of raw materials required to meet normal production, so as to avoid “sewing pins”. “The phenomenon of storage and the intersection of raw material storage areas.

4 Quality monitoring during storage of raw materials

During the storage process, some raw materials are prone to deactivation or oxidative rancidity due to long storage time or poor storage environment. Therefore, attention should be paid to monitoring the quality changes. Grease is one of the common raw materials that are prone to quality changes. The deterioration of oil is mainly caused by an increase in peroxide value, an increase in acid value, and oxidative decomposition to produce various harmful aldehydes, ketones, acids, etc. Animals consume degraded oils. After the disease occurs, the production performance is reduced. In order to control the quality of oils and fats, in addition to the correct storage of oils to prevent oxidative rancidity, the quality of long-term storage of oils should be monitored. The indicators include acid value and iodine value to determine the content of free fat and unsaturated double bonds in oil to judge the quality change of oil. Happening. The freshness of fishmeal is an important indicator affecting the application effect and feeding safety. If the fishmeal is stored in the warehouse for a long time, it may be caused by microbial contamination, fatty acid deterioration, self-ignition of fishmeal and other factors, causing its protein decomposition and corruption, fatty acid oxidation and rancidity, and protein coking. Equal metamorphism. During the storage of fishmeal, the quality changes should be determined by monitoring proteins, fatty acids, etc. Normal fresh fishmeal has a strong fishy scent, while spoiled fishmeal has a scent, ammonia, rancid, halo or burnt smell. Quantitative detection of mass change conditions can be used to evaluate the freshness of fish meal protein by using volatile base nitrogen and histamine content. The volatile base nitrogen content of normal fresh fish meal is less than 110~150mg/100g depending on the grade, while histamine The content is less than 300~1500mg/g. In addition, the acid value is also an important indicator for evaluating the freshness of fishmeal fat. Due to factors such as poor storage conditions and long storage time, the oil will increase the oxidative rancidity of the oil, produce bad odor, increase the acid value, and affect the quality of the fish meal. The acid value of normal fresh fishmeal is less than 3-7 mg/g depending on the grade.

To monitor the changes in the quality of raw materials during storage, it is necessary to pay attention to the quality of raw materials that have been stored for too long, based on the full understanding of the types, quantities and quality of raw materials, especially in the high temperature season. The impact of quality is even more pronounced. Raw materials that are prone to deterioration during storage are related to their physical and chemical properties. For example, raw materials with high moisture content are prone to mildew and deterioration during storage; raw materials with high oil content are prone to rancidity; high-protein raw materials are prone to protein degradation and spoilage. . To this end, raw material storage is also one of the important links in the quality control of feed ingredients. Tracking the quantity and quality of storage materials in real time has important practical significance for familiarity with raw material quality and rational preparation of compound feed.

In summary, the raw material storage is included in the quality control system, and the quality control of feed ingredients is comprehensively carried out from four aspects: on-site quality control of raw materials, laboratory testing of raw materials, storage and storage of raw materials, and quality monitoring during storage of raw materials. It has important practical significance for ensuring the implementation of feed formula and the quality of feed products. Product quality is the guarantee for enterprise development. It tracks the nutrient and physicochemical properties of raw materials in real time, rationally uses feed ingredients to prepare compound feeds to maximize the potential of animals, maximizes the effective nutrient function of feed ingredients, and optimizes economic benefits. This is also the quality of feed ingredients. The practical significance of control.